Large RO Desalination Machine

MINGMO is a global supplier with 20 years of experience in water treatment, dedicated to providing customers with various seawater desalination machines to meet the different applications and needs of multiple industries.

Contact us to get free water treatment solutions.

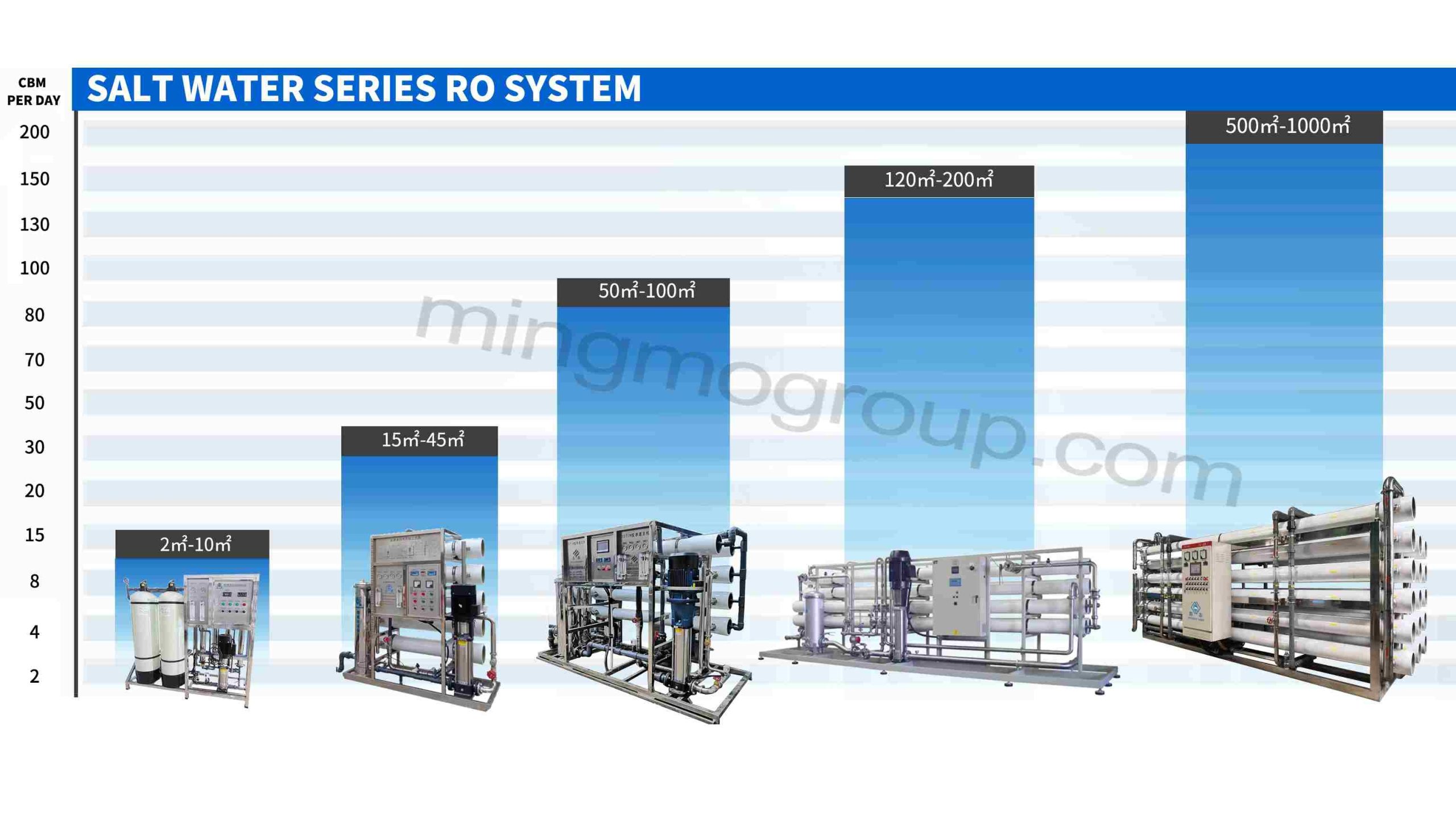

Our large reverse osmosis desalination machines support capacities from 5m3/day to 1000m3/day. If you want a desalination system with a smaller capacity, please refer to our commercial desalination machines.

What Is A Reverse Osmosis Desalination System?

Reverse osmosis is currently the most important technical means to achieve seawater desalination. It is a device that uses reverse osmosis technology to convert salty seawater (usually with a salt content of more than 10,000 ppm) into fresh water. Its core component is the reverse osmosis membrane, which has a tiny pore size (usually around 0.1 nanometers) and can effectively separate dissolved salts, colloids, bacteria, and other impurities in water.

The Principle of Reverse Osmosis(RO) Desalination Technology

The principle is: driven by pressure, water molecules pass through the semipermeable membrane and enter the low-pressure side of the membrane, while the salt in the seawater is blocked on the high-pressure side of the membrane and discharged with the concentrated water, realizing an effective separation process.

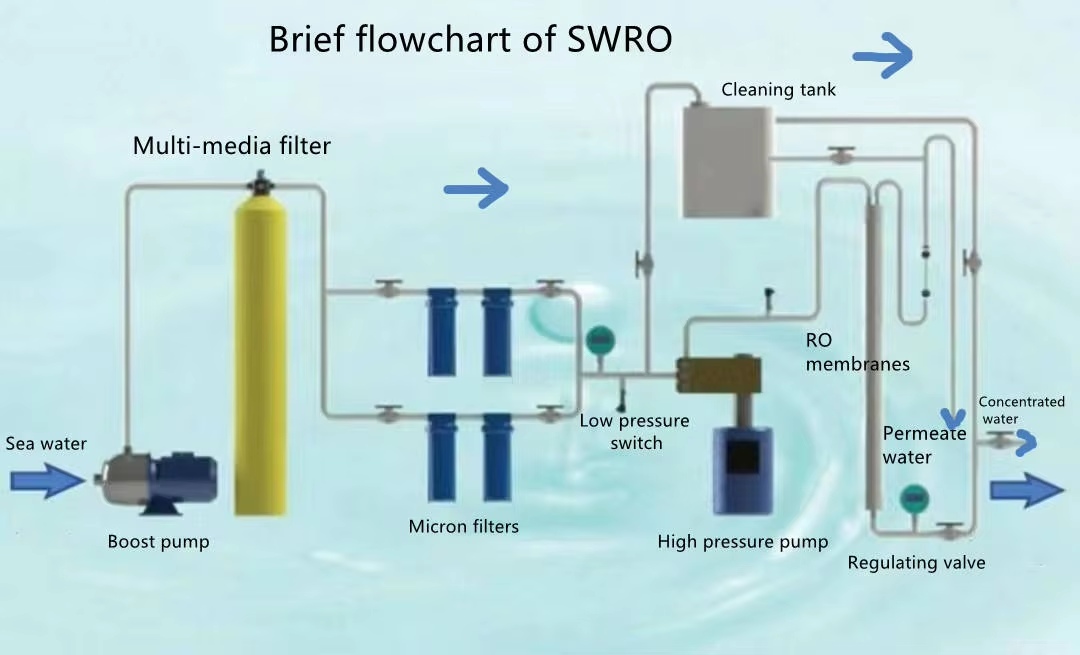

At MINGMO, a complete set of reverse osmosis desalination system main accessories include the following key components:

- Membrane assembly

- High-pressure pump

- Energy recovery device

- Security filter

- Pretreatment system

- Valves and instruments

- Flushing pump

- Auxiliary equipment and supporting pipelines

Together, these accessories constitute a complete reverse osmosis seawater desalination system that realizes an efficient and stable seawater desalination process through mutual cooperation and coordination.

What Are The Filtration Processes in A Reverse Osmosis Desalination System?

Generally speaking, the filtration process in the desalination process usually includes the following main steps:

Preprocessing

Pretreatment is an important step before desalination, and its purpose is to remove suspended matter, colloids, bacteria, viruses, and other substances in seawater. Generally, the untreated seawater is transported to the pretreatment tank by a booster pump, due to the high TDS (total dissolved solids) and saltwater corrosion.

MINGMO uses FRP or carbon steel materials as pretreatment tanks. Common pretreatment methods include sedimentation, multi-media filters (such as quartz sand and activated carbon filtration systems), and ultrafiltration technology to further remove impurities in the water.

Pressurized Delivery

After the water enters the security filter, we use a high-pressure pump to pressurize the pre-treated seawater and pass it through the reverse osmosis membrane.

At MINGMO, you can choose high-pressure pump brands according to your needs and budget, such as Grundfos, Danfoss, and CNP.

Reverse Osmosis Process

Applying a pressure higher than the natural osmotic pressure on the high-concentration aqueous solution side allows water molecules to pass through the semipermeable membrane into the low-concentration aqueous solution side, while other components in the solution (such as salt) are blocked on the high-pressure side of the membrane and discharged with the concentrated solution, thereby achieving effective separation.

Depending on your needs and budget, we can choose different brands of reverse osmosis membranes. For seawater desalination projects, we generally use DOW Filmtec, Toray, Vontron, Hydranautics, and LG brand SW RO membranes.

Disinfect

After a reverse osmosis system, a disinfection process is usually performed to ensure the safety and quality of the final product. Commonly used disinfection methods include adding sodium hypochlorite bactericide and alkaline solution.

Discharge of Concentrated Brine

The concentrated seawater discharged from the reverse osmosis system contains high salt content and is usually discharged into the sea or recycled to a pretreatment clear water tank for reuse.

Our reverse osmosis seawater desalination system has the remarkable characteristics of simple equipment, high efficiency, small footprint, easy operation, no phase change, no heat source, low energy consumption, and strong adaptability. The entire seawater desalination process involves meticulous operation and strict control of multiple links to ensure that the final freshwater meets drinking water standards.

FAQs

Q: What information should I provide before purchasing the Seawater desalination system?

A: The pure water production capacity (liters/day, liters/hour, GPD) you want, raw water environment or water quality analysis report, applicable power supply voltage and phase, equipment scene layout, etc.

Q: Does the equipment support customization?

A: Our equipment supports on-demand customization, and accessories, capacity, and voltage can be customized according to your needs and budget.

Q: Can other brands’ logos be added to the equipment?

A: Yes, we support adding other brands’ LOGO.

You can check our FAQ page or contact us directly if you have more questions. We will reply within 8 hours.

Containerized Seawater Desalination System

Containerized Seawater Desalination System Seawater Desalination System

Seawater Desalination System Small/Marine Watermaker Systems

Small/Marine Watermaker Systems RO+EDI Ultrapure Water System

RO+EDI Ultrapure Water System Media Filter

Media Filter Brackish Water Reverse Osmosis Treatment System

Brackish Water Reverse Osmosis Treatment System Ultrafiltration System vs. Reverse Osmosis System: Which One Should You Choose?

Ultrafiltration System vs. Reverse Osmosis System: Which One Should You Choose?