Small/Marine Watermaker Systems

MINGMO’s small desalination system or watermaker for boats is specially designed according to the particularity of boats/yachts and other applications. It has the characteristics of compact structure, small size, light weight, small space, easy installation, strong adaptability, simple operation and convenient maintenance.

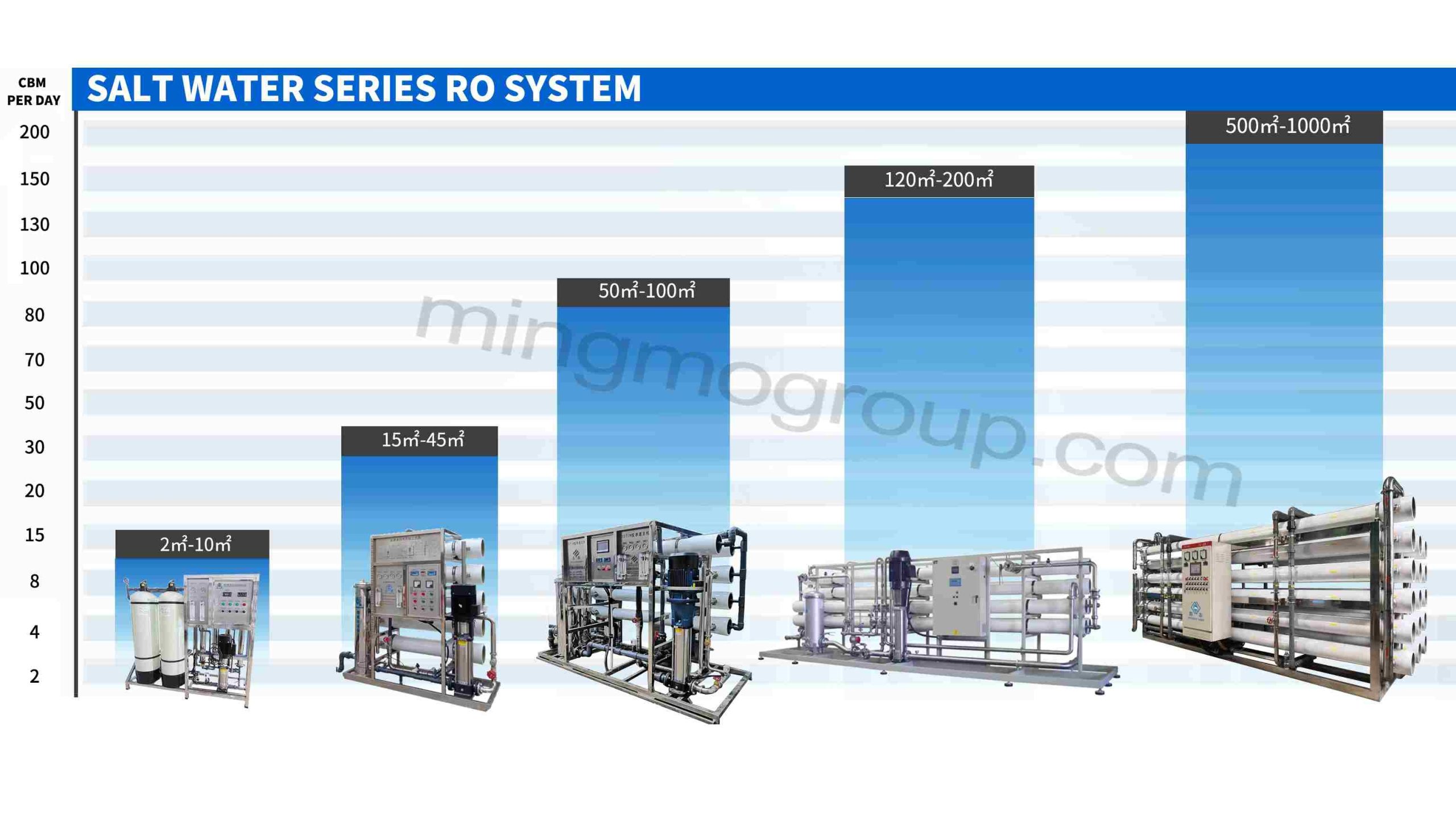

Here we only introduce small-scale and marine reverse osmosis watermaker systems. Please check out our industrial desalination systems if you need large-scale desalination equipment.

Product Description

MINGMO‘s small and marine water maker are designed and produced with full consideration of customer requirements. They are specially designed to suit the particularities of boats/yachts and other applications. Marine/small desalination machines are compact in structure, small in size, light in weight, easy to install, highly adaptable, simple to operate, and easy to maintain. They can be installed in narrow and crowded cabins, decks, crew cabins, aisles, etc.

The equipment is made of stainless steel and corrosion-resistant materials, which improves the equipment’s physical properties such as corrosion resistance.

The desalination process uses reverse osmosis (RO) technology, with a desalination rate of up to 98%. Reverse osmosis membranes and high-pressure pumps are mainly used to remove impurities (such as salt and minerals) in the water, thereby obtaining pure water to meet the crew’s needs for drinking, cooking, and showering.

Our equipment has CE/ISO international certification, and all devices can be customized according to your needs. Whether you have project requirements for yachts, cruise ships, ferries, or seaside resorts, MINGMO has a seawater desalination system suitable for your project.

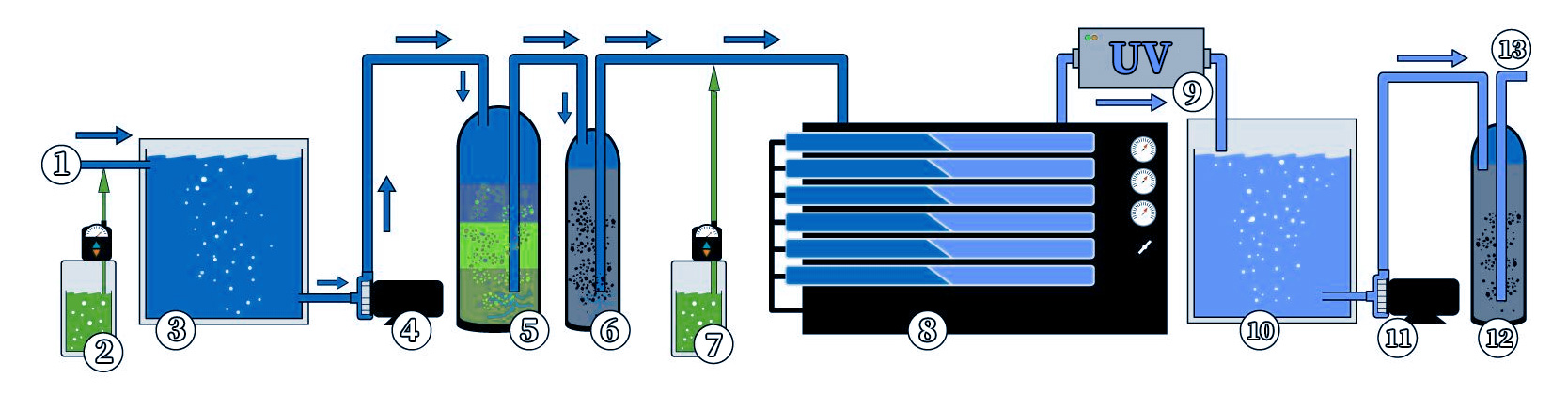

Seawater Watermaker System Process Schematic Diagram

- Raw water inlet

- Pre-chlorination dosing system

- Raw water storage tank

- Feed and backwash pumps

- Multi-media filter filtration (reduces turbidity and suspended solids)

- Activated carbon filter filtration (removes chlorine, odor, taste, and organic matter)

- Antiscalant dosing system

- Seawater reverse osmosis system filtration

- UV water disinfector

- Product water tank

- Booster pump

- pH-neutralized calcite filter

- Usable water

Watermaker Parameters

- 316 frame

- With reverse osmosis cleaning agent

- Touch screen

- PLC control system

- Inlet TDS: less than 50000PPM

- Production TDS: less than 100PPM

- Working temperature: 5-48°C

- Voltage: 220V-380V (with power plug)

- Desalination rate: 98%

- Freshwater output: 200L-2000L/hour

Mini Seawater Watermaker System

- 316 frame

- With reverse osmosis cleaning agent

- Inlet TDS: less than 40000PPM

- Production TDS: less than 500PPM

- Working temperature: 5-45°C

- Voltage: 220V-380V (with power plug)

- Desalination rate: 98%

- Freshwater output: 20L-50L/hour

Equipment Maintenance

Due to the high salt content and TDS of seawater, the maintenance and care of seawater desalination equipment is essential if you want the equipment to run longer. In order not to affect the filtering effect, the multi-stage filter should be cleaned regularly to prevent the filter material from being blocked. Chemical cleaning agents (such as acid cleaning and alkaline cleaning) should be used regularly to remove the scale and organic matter on the membrane surface, extend the life of the reverse osmosis membrane, and replace the reverse osmosis membrane in time.

Before purchasing a desalination system, you will need to provide us with the following information:

- Flow rate (liters/day, liters/hour, GPD)

- Raw water analysis report

- Seawater source

- Substances that must be removed

- Available power supply voltage and phase

- Site layout of equipment

Containerized Seawater Desalination System

Containerized Seawater Desalination System Seawater Desalination System

Seawater Desalination System RO+EDI Ultrapure Water System

RO+EDI Ultrapure Water System Media Filter

Media Filter Brackish Water Reverse Osmosis Treatment System

Brackish Water Reverse Osmosis Treatment System Large RO Desalination Machine

Large RO Desalination Machine Ultrafiltration System vs. Reverse Osmosis System: Which One Should You Choose?

Ultrafiltration System vs. Reverse Osmosis System: Which One Should You Choose?