1000LPH RO plant in food workshop

This is a generic system that applied in food & beverage workshop that reaches balance of cost & performance. The source water is from underground with TDS=800ppm, EC=400μS/m, hardness=450mg/L, so a softener tank was added to the system. The outlet water with TDS≤7ppm, EC≤3.5μS/m, hardness≤50mg/L that goes above the national standard.

- Project: 1000LPH reverse osmosis filtration plant all SS304 tanks and pipelines

- Processing capacity: 1000L/H

- Desalination rate: ≥99%

- Revovery rate: 50%-75%

- Raw water: river water, TDS: 1200ppm

- Product water: High purity sterile water for food processing, TDS: ≤15ppm

- Pretreatment: Sand filter+carbon filter+water softener+1um micron filter

- RO module: 4*Vontron ULP21-4040 membrane+UV sterilizer

- Valve: Runxin timer automatic

- Controller: Preset program

- Power consumption: 2.25KW max

Feed water limits

- Max operating pressure: 600psi(4.13Mpa)

- Temperature: 5-45°C (113°F)

- Max chlorine concentration: 0.1mg/L

- Max feed flowrate: 3.6 m3/hr(16.0gpm)*4

- Max feed turbidity: 1.0 NTU

- Max feed SDI (15 minutes): 5.0

- Feed pH range ( nominal): 2.0-11.0

Containerized Seawater Desalination System

Containerized Seawater Desalination System Seawater Desalination System

Seawater Desalination System Small/Marine Watermaker Systems

Small/Marine Watermaker Systems RO+EDI Ultrapure Water System

RO+EDI Ultrapure Water System Media Filter

Media Filter Brackish Water Reverse Osmosis Treatment System

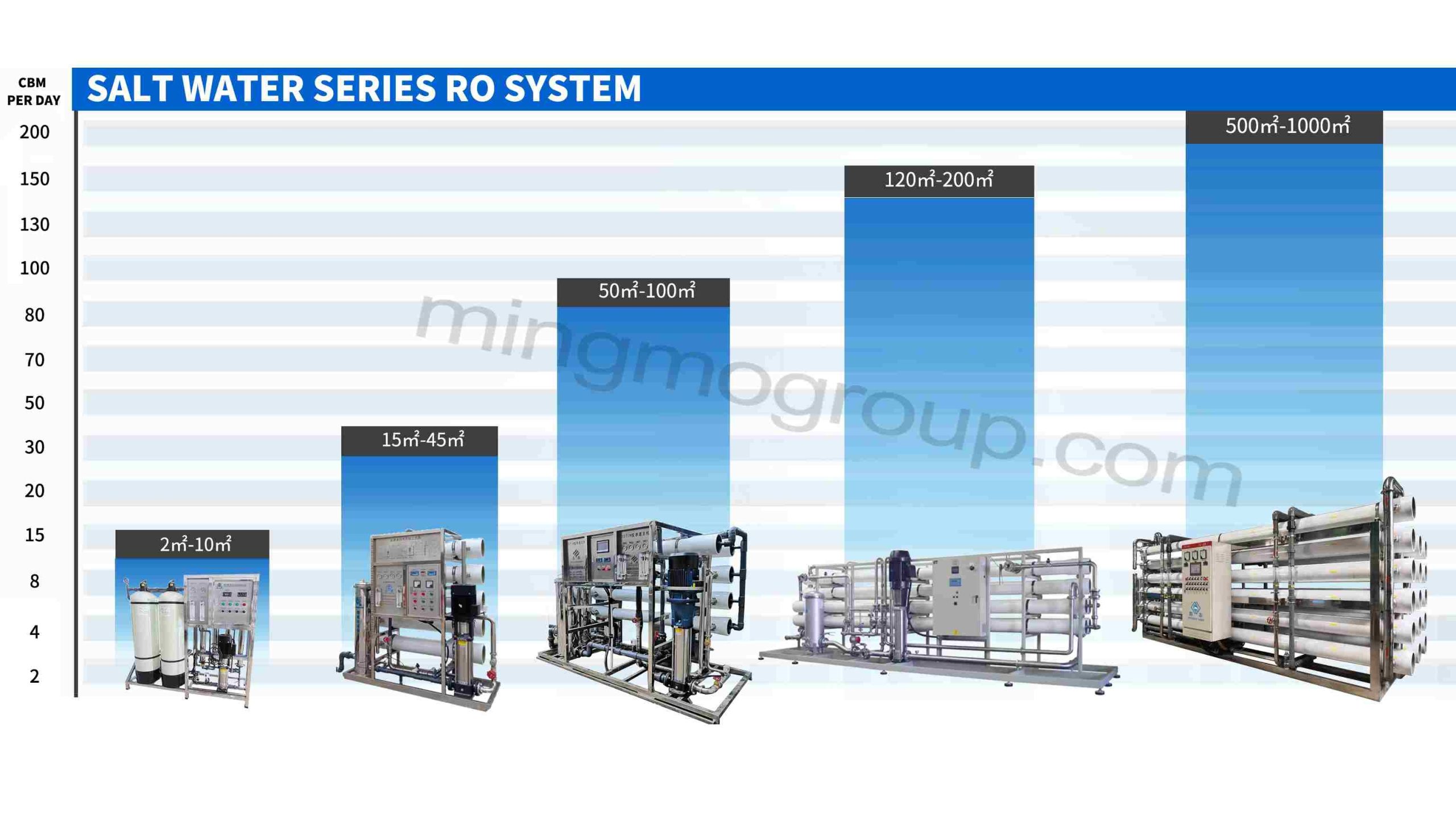

Brackish Water Reverse Osmosis Treatment System Large RO Desalination Machine

Large RO Desalination Machine Ultrafiltration System vs. Reverse Osmosis System: Which One Should You Choose?

Ultrafiltration System vs. Reverse Osmosis System: Which One Should You Choose?